ABOUT NISOURCE

NiSource Inc. (NYSE: NI) is one of the largest fully-regulated utility companies in the United States, serving approximately 3.3 million natural gas customers and 500,000 electric customers across six states through its local Columbia Gas and NIPSCO brands. The mission of our approximately 7,200 employees is to deliver safe, reliable energy that drives value to our customers. NiSource is a member of the Dow Jones Sustainability – North America Index and is on Forbes lists of America’s Best Employers for Women and Diversity. Learn more about NiSource’s record of leadership in sustainability, investments in the communities it serves and how we live our vision to be an innovative and trusted energy partner at NiSource.com.

BUILDING A SUSTAINABLE FUTURE

Central to NiSource’s aspirational commitment to sustainability is our continued focus on building a sustainable and cleaner energy future in a way that provides financial, economic, social and environmental benefits to all stakeholders – including our employees, customers and communities.

In 2022, we continued to explore innovate, new pathways to reduce emissions through the use of hydrogen, renewable natural gas and emerging technologies. We furthered our ongoing energy infrastructure modernization, renewable electric generation investments and other strategies responsible for significant reduction in emissions. And NiSource advanced its sustainability plans with the announcement of a net zero goal which places our commitment among industry leaders – reaching net zero Scope 1 and 2 greenhouse gas (GHG) emissions by 2040.

As we advance toward these goals, we understand that the transition to a sustainable energy future must keep people at the center of any decisions while balancing multiple factors – including reliability, affordability, resilience and environmental impact. That means we must continue to provide customers with access to a reliable supply of energy at a cost that customers value as we thoughtfully move forward.

Significant transformation and tangible progress continues to occur across the energy industry, and NiSource remains well positioned in enabling our customers to pursue their energy and sustainability preferences safely, reliably and affordably now, and into the future.

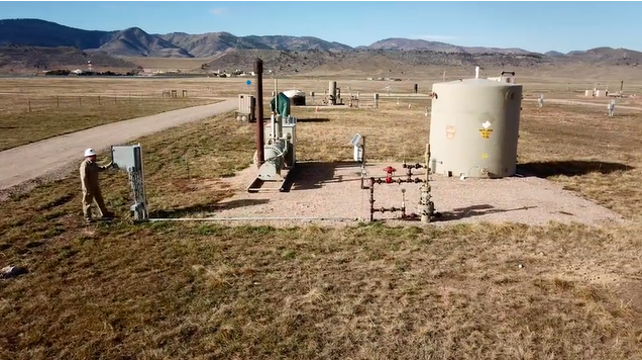

EXPANDING ADVANCED LEAK DETECTION

NiSource has continued our partnership with Picarro, an industry leader in analytics-driven methane detection, and deployed advanced mobile methane detection vehicles in Indiana, Kentucky Maryland, Ohio, and Pennsylvania and Virginia.

These Picarro-equipped vehicles are designed to “sniff” the air and identify potential natural gas leaks using proven technology that’s 1,000 times more sensitive than traditional leak detection equipment.

Resources like the Picarro-equipped vehicles are critical in affirming our commitment to safety as well as reaching our goal of net zero greenhouse gas emissions by 2040.